CORROSION PROTECTION COATINGS: for every type of protection.

Corrosion has many causes. Wetterwart® coatings provide effective protection against corrosion with innovative solutions individually tailored to your needs.

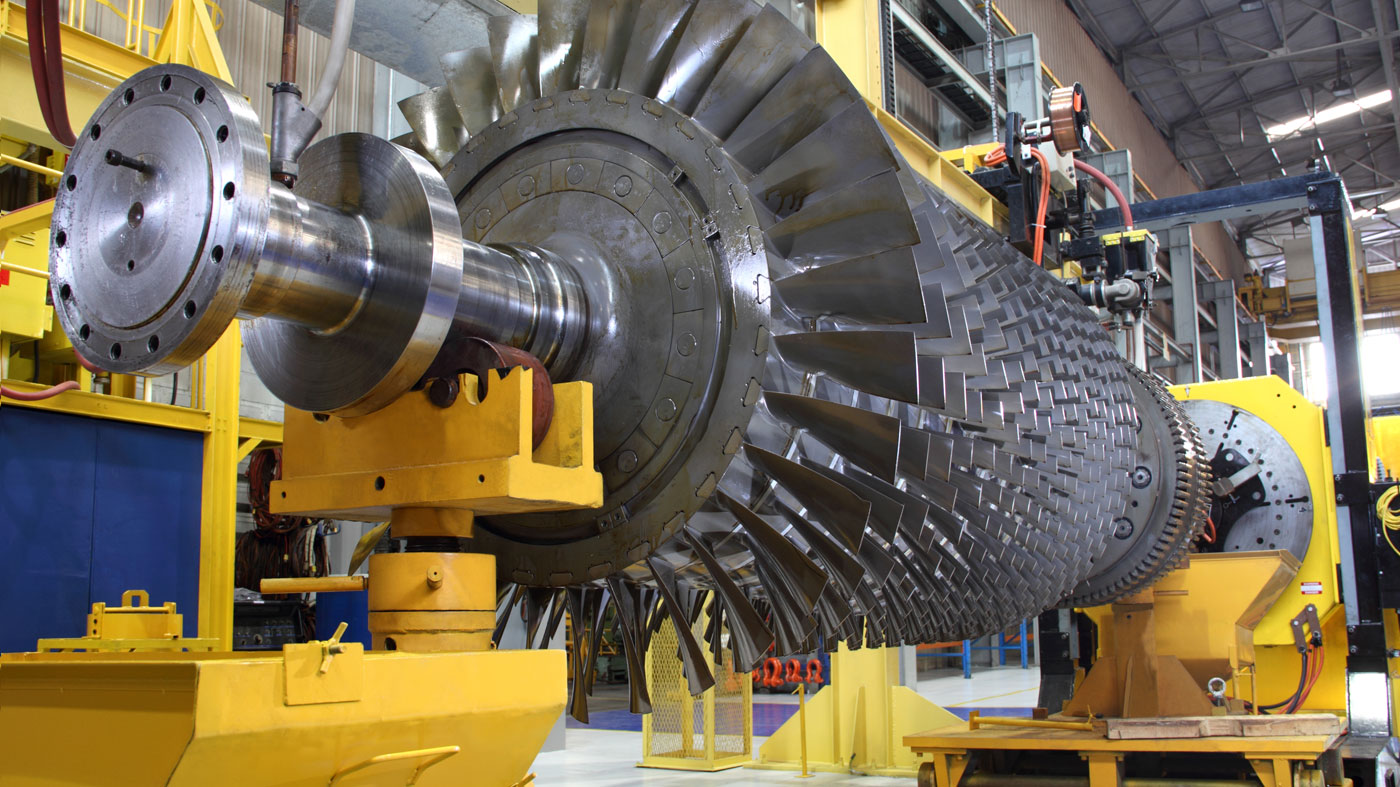

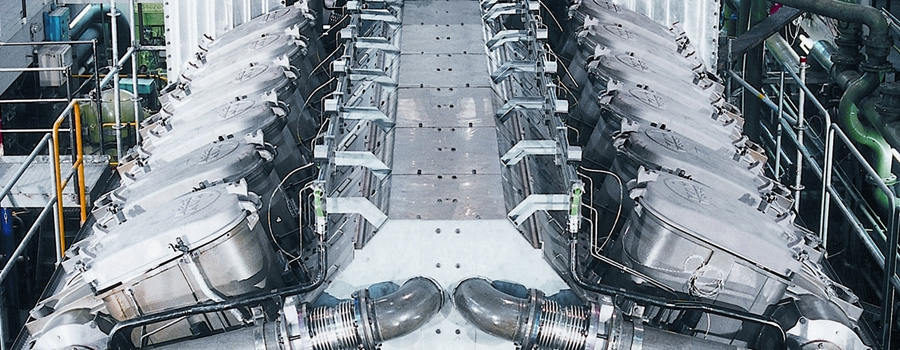

Corrosion protection coatings from our Wetterwart® product series permanently protects engines, plant equipment, construction machinery and steel structures from continued exposure, effectively safeguarding the long-term value of your assets.

e.g. 2K Ultra-High-Solids One-Coat Epoxy 609-AL:

high-performance coating

e.g. 2K Acrylic Coating 966:

for construction machinery, tool manufacturing equipment, steel structures

e.g. Ultra-High-Solids Rust Barrier SL-2306: for engines,

machinery and plant construction

×Wetterwart-Lacke

2K Ultra-High-Solids One-Coat Epoxy 609-AL

Surface-tolerant epoxy

| PRODUCT DESCRIPTION | Self-priming high-performance coating with low VOC content. |

|

|

|

×Wetterwart-Lacke

Wetterwart 2K Acrylic Coating 966

Aliphatic polyurethane

| PRODUCT DESCRIPTION | 2-component polyurethane-based coating. |

|

|

|

×Wetterwart-Lacke

Ultra-High-Solids Rust Barrier SL-2306

High Build Epoxy

| PRODUCT DESCRIPTION | Self-priming high-performance coating with low VOC content. |

|

|

|